Pi proportional integral controller or on off settings type and thickness of insulation plates platen heater and the molding process as previously described.

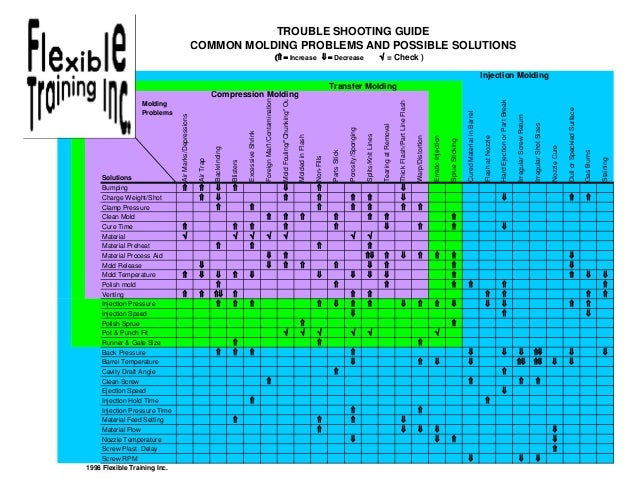

Rubber injection molding troubleshooting.

When injection molding liquid silicone rubber certain problems can occur that directly affect the quality of the final product in spite of the great planning that may have gone into material selection machine process and the processing parameters.

Rubber injection molding may have higher initial startup costs when compared to other molding processes.

Injection molded plastic begins its journey through the part tooling via an entry section called a gate.

Evaluating the root causes of rubber molding defects through virtual molding.

Stock temperature too low mould temperature non uniform or too low mould fill too fast or too slow excess mould lubricant scratched or dirty mould surface fill speed and or packing time too low inadequate venting improper gate location or design.

1 increase injection pressure and injection speed to enhance shear heat 2 increase the amount of injection 3 increase material cylinder temperature and mold temperature.

Air traps is that air is trapped in the cavity to create bubbles in the part.

Increase stock temperature by increasing back pressure and or barrel temperature.

If these issues are not controlled promptly and properly they could end up resulting in damage to the machine mold and finished product.

Liquid silicone rubber injection molding troubleshooting.

Tool modification can also be difficult with the machine s runner system.

Common issues with rubber injection molding.

Check injection throttle position and if possible increase its setting.

Material is also limited to high flowing compounds when it comes to rubber injection molding.

Virtual molding will auto matically calculate heat flow through all the mold components and the heat lost from the cavities due to radiation while the mold is open.